Khoom Carbide Drills General Machining Boring Tool

Lus piav qhia luv luv:

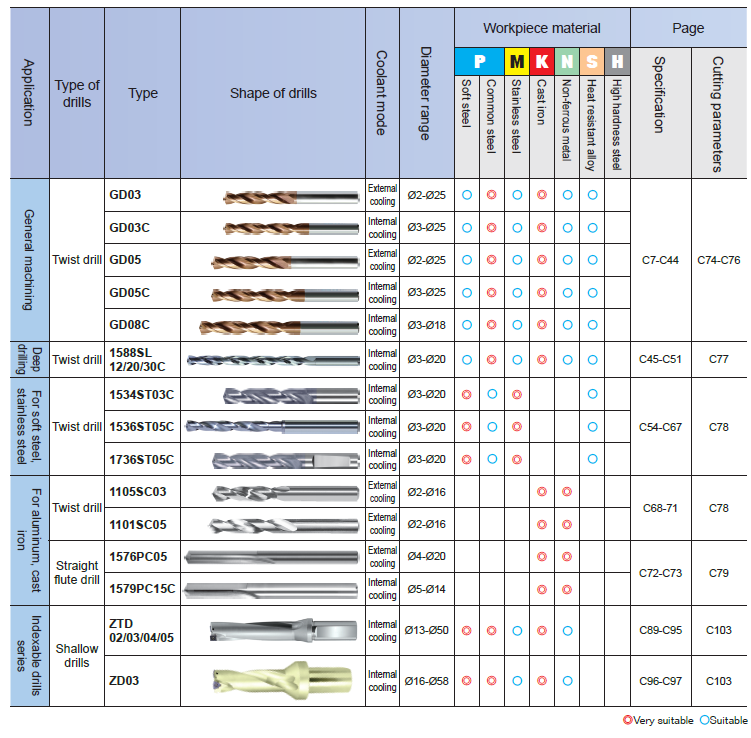

GD series General-purpose twist laum ntau yam, rau kev ua haujlwm siab hauv ntau yam khoom xws li P (steel), M (Stainless steel), K (cam khwb cia hlau). hom raws li koj xav tau. Peb lub tuam txhab kuj tuaj yeem kho cov tungsten carbide laum (drills, carbide burr thiab lwm yam) raws li koj xav tau.

Khoom Taw Qhia

Cov cuab yeej tho txawv tshaj qhov pom

| Kev xyaum | Khoom carbide xyaum |

| Indexable ntiav xyaum xyaum | |

| Reamers | Khoom carbide reamers |

| Threading cutters | Khoom carbide threading cutters |

| Khoom carbide threading mills |

Drilling cuab yeej txheej txheem cej luam

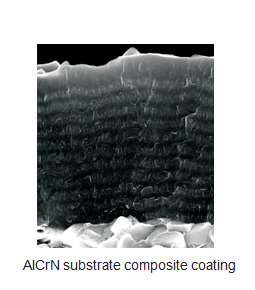

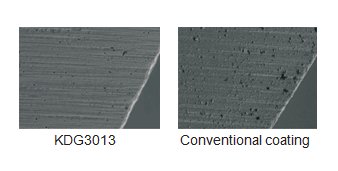

Coated qib:TSI 3013Tshiab AlCrN substrate composite txheej, nrog rau kev puas tsuaj zoo heev thiab kev sib txuas ua haujlwm, txhim kho kev ruaj ntseg ntawm ntug ntxig. Cov txheej txheem tshwj xeeb tom qab kho cov cuab yeej siv tau zoo txo qhov kev txiav tawm kom ua haujlwm zoo dua nti thiab kev ruaj ntseg dua.

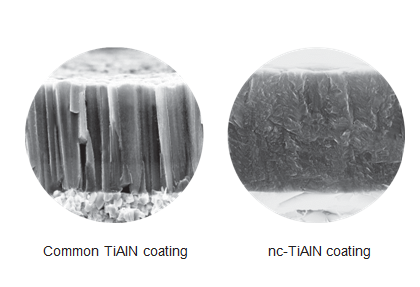

KWD 303:Ultra-fine carbide substrate nrog lub zog siab, toughness thiab hnav tsis kam, ua ke nrog nano-structured nc-TiAlN txheej aiming ntawm optimizing drilling hauj lwm, ua kom cov cuab yeej muaj siab heev toughness thiab hardness. Cov txheej txheem txheej txheej tshwj xeeb muab cov cuab yeej du nto thiab hnav zoo heev, thiab zoo thermal stability thiab tshuaj stability muab kev tiv thaiv zoo rau kev txiav ntug.

Nta

GD series muaj ntau yam kev siv. Muaj qee qhov nta raws li hauv qab no:

1. Ntau yam, rau kev ua haujlwm siab hauv ntau yam khoom xws li P (steel), M (stainless steel), K (Cast iron).

2. Linear txiav ntug nrog lub zog siab. Optimized xyaum taw tes qauv rau kev txiav zoo dua.

3. Simulation ua ke nrog kev sim rau kev ua tau zoo tag nrho.

4. Kev tshaj lij tom qab kev kho mob rau cov txheej txheem kom ntseeg tau tias tsis muaj kev ua haujlwm siab ua haujlwm zoo.

5. Ob chav ntug-kab tsim rau kev txhim kho machining stability.

Kuaj kev sib piv ntawm inserts abrasion

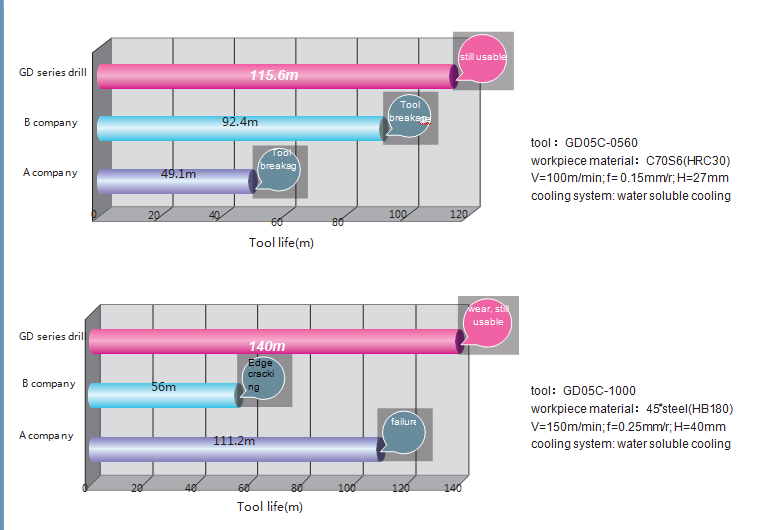

Lub neej ntev thiab ruaj khov

Zoo tshaj machining precision

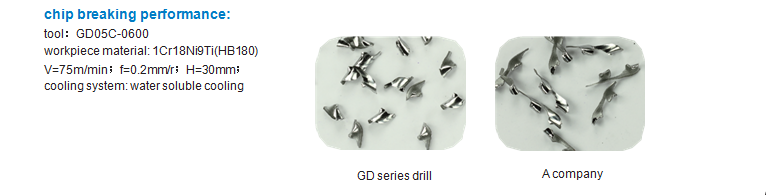

Zoo heev chip breaking kev ua tau zoo

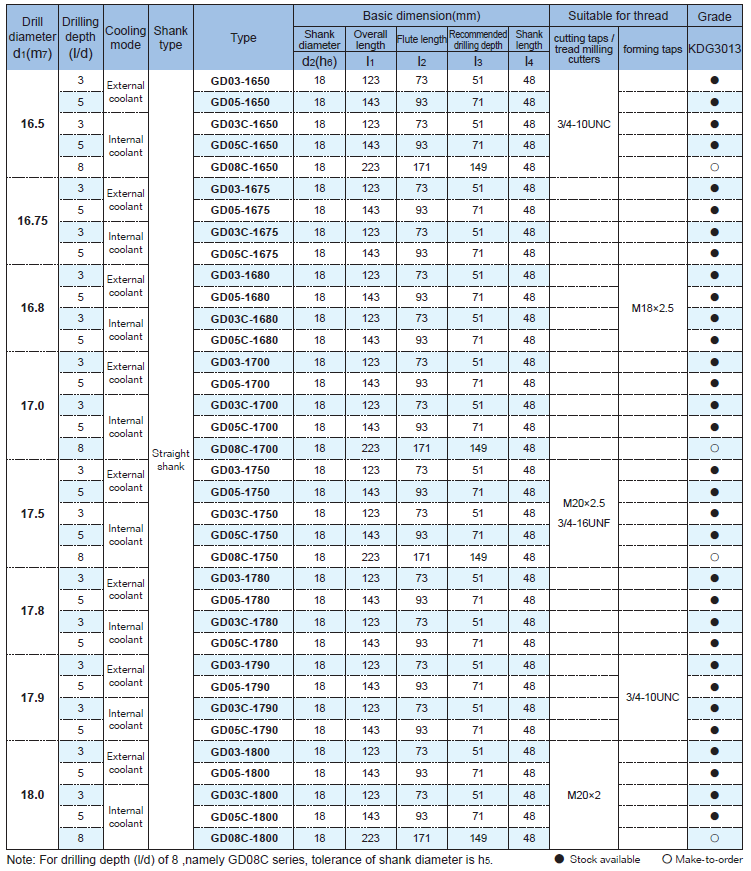

Parameter

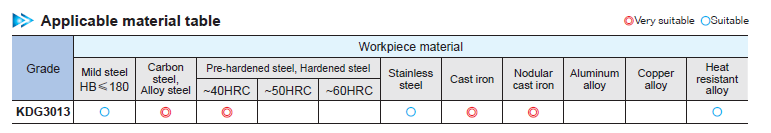

Daim ntawv thov

FAQ

Qhov sib txawv tseem ceeb yog kev ua tiav: qhov kawg mills yog rau milling, thaum lub laum khoom yog rau drilling thiab reaming. Txawm hais tias qee zaum, milling cutter kuj tuaj yeem drilling, tab sis nws tsis yog qhov tseem ceeb.

Yog tias hom peb muaj hauv Tshuag, txhua qhov ntau yuav OK.

Yog, peb tuaj yeem hloov kho rau koj raws li koj xav tau.

Ua ntej, cov khoom siv workpiece.

Thib ob, cov ntsiab lus dav: laum txoj kab uas hla, hom shank, qhov tob tob, lub raj nplaim ntev thiab tag nrho ntev, hom txias.

Thib peb, yog tias koj xav tau customized, muab peb cov duab kos yuav zoo dua.